|

Main Page // Academic Projects // Design Projects // Publications // Career & Education // CoLab Site // Send an Email // ........................................................................................................................... |

|

|

|

// Design Pedagogy // Contribution to a book chapter, 2015; with Dr M.A. Evans & Dr R.I. Campbell (Above) This book chapter, co-written with M.A. Evans and R.I. Campbell reports on research to enhance communication during product development by making tacit knowledge on the use of design representations explicit for both students and practitioners. This was achieved through the development of two design tools called CoLab and iD Cards. The report concludes that the use of appropriate research methods that integrate literature based sources with practitioner engagement has the potential to elicit valuable and unexpected tacit knowledge that can contribute to student learning. It also acknowledges that whilst the outcomes from such research can be enthusiastically received, translation into a format for effective dissemination can be a challenging and time-consuming process. However, with confidence in outcomes and a desire to disseminate, opportunities can be identified if researchers are prepared to be flexible and adapt to stakeholder needs.

|

|

|

|

|

// Mat-Kit 3D Printing Filaments // University Knowledge Exchange Programme with L'Earth Ltd., 2014 (Above) Through market analysis, I identified

that there was an opportunity to use bio-composites from rice husks to

be reconstituted for 3D printing. Through a university Knowledge

Transfer Programme, I was provided financial support to collaborate with

an Winrigo and L'Earth to create a brief to develop a range of 3D

printing filament products. Working closely with their team of polymer

scientists, retail experts and polymer extrusion specialists, the

Mat-Kit series of filament products was created in 2014 and launched in

2015, offering a range of high quality materials with excellent

stability and incredible value for money. I played a key role in the

design of the packaging by suggesting a number of innovative features

such as the honeycomb structure for visual impact, and a cut-out window

to identify the type of filament inside. This product won the

international World Star 2014 Award for excellence in packaging.

|

|

|

|

|

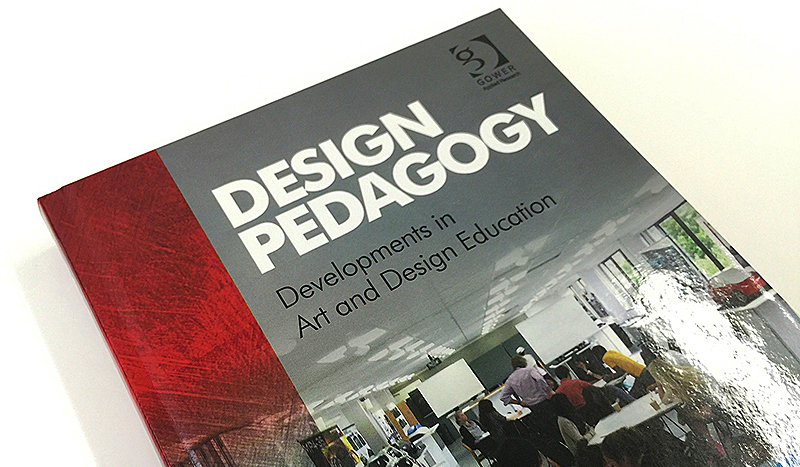

// Digital Reconstruction of a Tramcar // with Joel Mann, Lee Clark & Efstratios Aligizakis for the Leicester Heritage Transport Trust, 2014. (Above) This tram was built in 1904 by Dick Kerr and Co. of Preston. The top deck was originally open, leaving passengers to face bad weather. Top deck covers were later added to all open top trams in Leicester between 1913 and the 1920s. Further changes were made in the 1930s when the tram was fully enclosed to modernise. The stairs were reversed, which blocked the driver’s vision of traffic over his left shoulder. One of the steps was made with holes to allow the driver to get a better view. To prevent the conductor from using this feature to view ladies’ ankles which was a serious offence, a ‘decency flap’ was provided to cover the holes when not in use. Leicester 76 was withdrawn from service in 1947 and now resides in the National Tramway Museum in Crich, Derbyshire. Due to the historical links with this tram and the city of Leicester, the Leicester Transport Heritage Trust wanted to produce a digital blueprint. I was commissioned by them to lead 3 researchers to digitally rebuild the entire tram and the 24 month project was completed in December 2014. A 3D printed 1:22.5 scaled model has been produced and is undergoing assembly stages. Principle Investigator: E. Pei

|

|

|

|

|

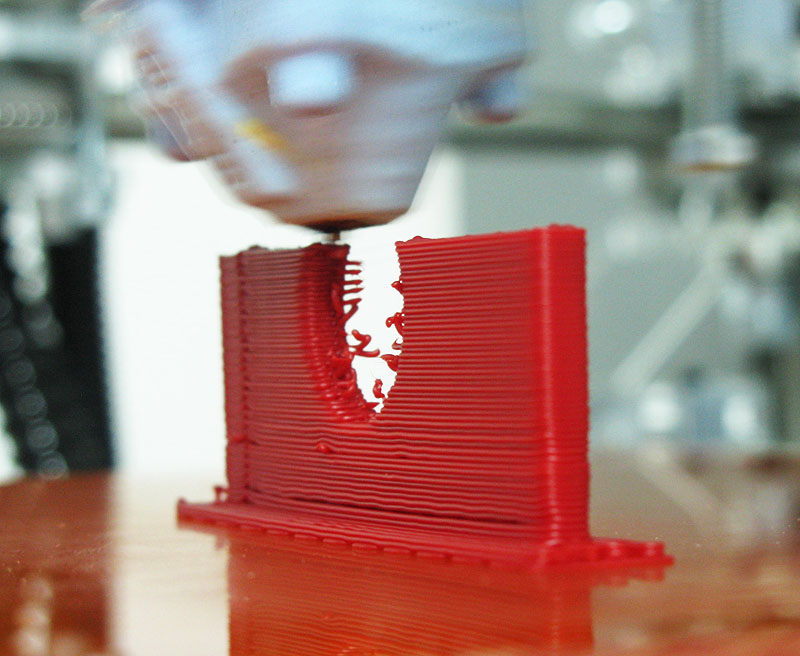

// Direct Deposition of Polymers onto Textiles // with Professor Jim Shen & Jennifer Watling, 2014 (Above) Achieving polymer deposition on textiles

requires an understanding of material properties, adhesion,

compatibility and deposition techniques. As the Principal Investigator,

I had control over the research budget and expertise of material

scientists and polymer experts. Working closely with experts and a

postgraduate student, we systematically conducted numerous trials and

recorded the results that has now been accepted for a journal paper.

This experiment contributed to new knowledge and extended our

understanding on how polymers could be directly printed onto fabrics

using 3D printers. The findings support future work on wearable

electronics and the production of customised medical products such as

orthopaedic braces. The experiments show that PLA, Nylon and ABS adhered

very well when printed onto Polywool, Cotton and Soy-based fabrics.

Functional parts such as fasteners and articulated features were

designed and printed onto the fabrics, paving way for functional use.

|

|

|

|

|

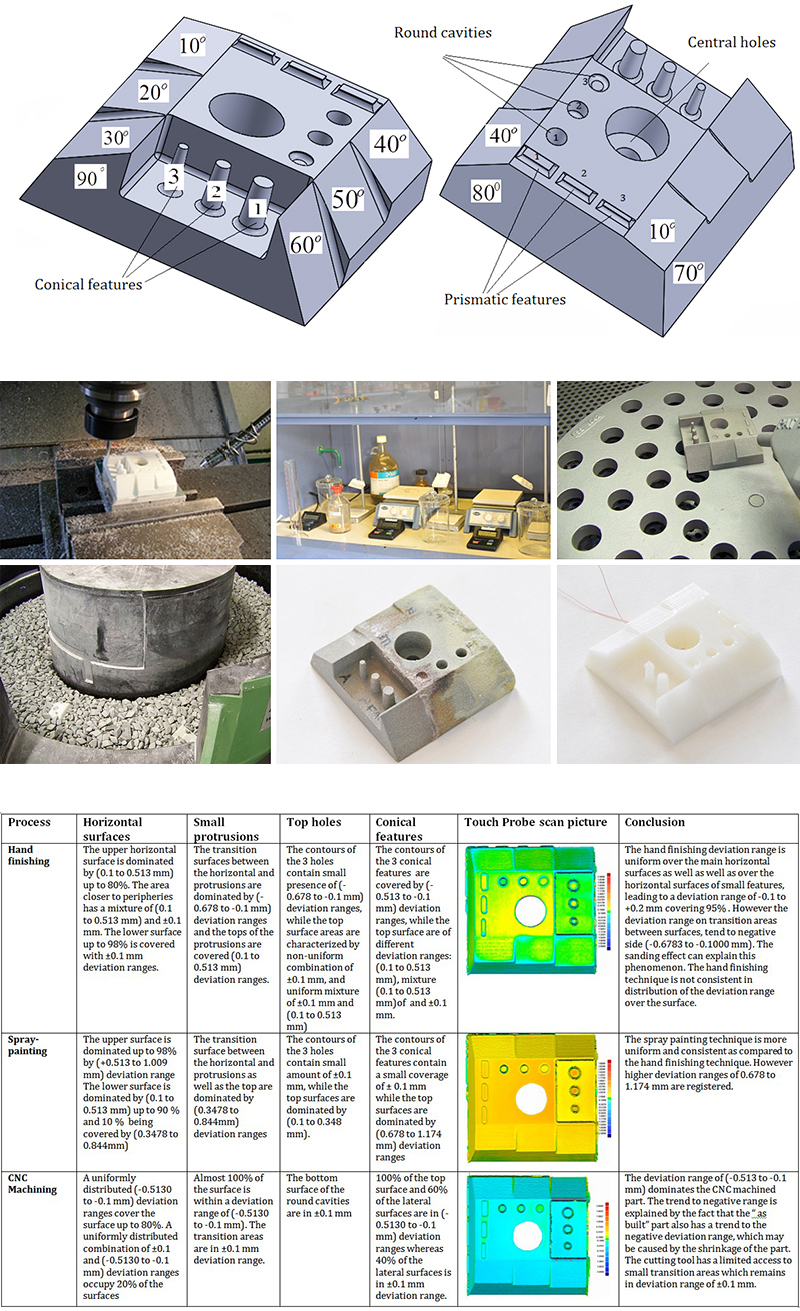

// Surface Finishing Techniques for Additive Manufactured Parts // with Kobus Van Der Walt, Joseph Nsengimana and Maruf Miah 2014 (Above) This research was to investigate the use of mechanical and chemical finishing methods for Alumide, Nylon and ABS parts produced from Laser Sintering and Fused Deposition Modelling. The sides of the test pieces were designed with different planar surfaces that demonstrate the stair-step effect with different build angles; truncated conical features to investigate whether smaller details will deflect or break during CNC machining; protruding prismatic features to examine the result of tumbling; and blind holes to determine whether processes such as spray painting will fill cavities. The pieces were post processed through tumbling, shot peening, hand finishing, CNC machining, spray painting and chemical treatment. A touch probe scanner quantitatively assessed the dimensional accuracy of the post processed parts and the results graphically represented for comparative studies. Principle Investigator: E. Pei

|

|

|

|

|

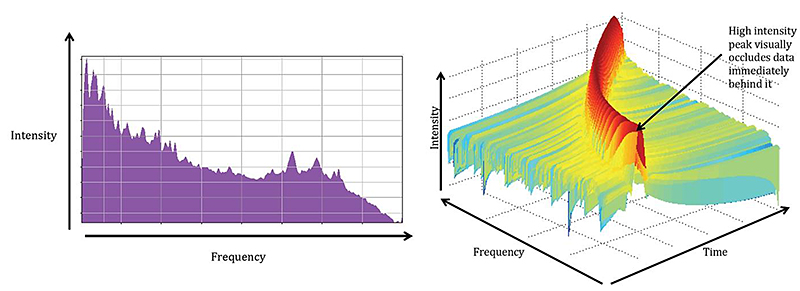

// Sound Spheres // De Montfort University, 2013; with Dr L. Picinali & C. Feakes (Above) The Sound Sphere is a physical representation of recorded sound. The surface is covered in ridges, which run around it laterally. Each of these ridges represent a set of frequencies within the sound, with low frequency at the bottom of the sphere (the bass); and high frequency at the top (the treble). The closer a ridge is to the north pole, the higher a band of frequencies it represents. Following these ridges laterally around the sphere is equal to observing the signal change over time (measure of time); and finally, the extent to which the ridge protrudes from the sphere represents the sound intensity at any given moment (the volume) - the more the ridge protrudes, the louder the sound is in that frequency at that given time. The Sound Sphere is being exhibited at the De Montfort University Fletcher Building foyer; was showcased at the university's Frontrunners evening; and featured in De Montfort University News and the Eureka magazine. Principle Investigator: E. Pei |

|

|

|

|

// Samian Wares // De Montfort University, 2013; with S. Manoj (Above) We were commissioned by the Leicester Arts and Museums Service to digitise decorated Samian Ware pieces (terra sigillata, fine red ancient roman pottery) dating from between 50BC to 3rd century AD and to reproduce these as replicas that could potentially improve the museum experience of partially sighted visitors through touch. The aim was also to examine the quality of the reproduced artefacts using SLA. The first image image is the digitised scan showing clear details, while the original piece is on the right and the reproduced pieces below. Challenges include non-contact scanning, capturing the motifs and designs on the relief-decorated ware (hunting scenes), and to circumnavigate issues of the reflective glaze-like surface. Principle Investigator: E. Pei |

|

|

|

|

|

|

// Replicating an Anglo-Saxon Spindle Whorl // De Montfort University, 2013; with A. Eland & R. Gautam (Above) Commissioned by the Leicester Arts and Museums Service, we were asked to replicate a 1500 year old rock crystal faceted spindle whorl that was dug near Lutterworth Road. A spindle whorl is a disc or spherical object fitted onto the spindle to increase and maintain the speed of the spin during weaving. Due to the mineral, initial 3D scans of the crystal were inaccurate. Subsequent fine-tuning resulted in two geometries - one from the scan data being dimensionally accurate; and another being geometrically perfect - an intervention using digital technology 1500 years later. The test pieces and final replica were fabricated with the use of 3D printing. Challenges include non-contact scanning and to circumnavigate issues of the reflectivity of the crystal. The exhibit can be seen at the Jewry Museum in Leicester today. Principle Investigator: E. Pei |

|

|

|

|

// Shock of the New

// Winchester School of Art, University of Southampton, 2010; with Dr Y.

Yin (Above) A review of the literature has found that research on older consumers in United Kingdom is limited; and data collection has been obtained mainly from surveys and questionnaires. This study as part of a research fellowship at the Winchester School of Art (University of Southampton) aims to investigate issues associated with food shopping among senior shoppers through the use of observations, interviews and audio recordings to triangulate the findings. Key problem areas identified include food being inappropriately placed; poor signage; over-stacking; and difficulty when using deep trolleys. The study also found a preference among elderly shoppers to purchase small food portions. The results from this research confirmed problems that senior consumers face and highlights the importance for retailers to consider their special needs. Principle Investigator: Y. Yin |

|

|

|

|

// ErgoCES // Brunel University, 2010; with

Dr H. Dong (Above) Inclusive design promotes the development of mainstream products, environments and services that are accessible and desirable to the widest range of users possible, including groups with specific needs such as older people and people with disabilities. This research study as part of a research fellowship at Brunel University reports a survey of designers with different levels of experience and analyses issues that affect their uptake of inclusive design. The survey also gathers evidence on existing tool use and the perceptions of the tools’ strengths and weaknesses, identifying features that designers would value in inclusive design tools. By understanding their requirements based on their levels of experience, it is proposed that this approach should lead to tools that are more attuned to designers’ needs, and as a result, increase the practical uptake of inclusive design. Principle Investigator: H. Dong |

|

|

|

|

// Digital Industrial Design // Loughborough

University, 2010; with Dr M.A. Evans (Above) This research investigated the viability of a fully digital industrial design process. The use of digital tablets, 3D CAD modelling, haptic modelling, graphic design and rapid prototyping were used. Data collection was captured by means of a design diary. Principle Investigator: M.A. Evans |

|

|

|

|

//

Entry Level RP Machines: How Well Can They Cope With Geometric

Complexity // Vaal University of Technology, 2010; with Professor Deon

de Beer & Dr R.I. Campbell (Above) I was invited as a Research Scientist to examine and assess the limitations of using Entry Level 3D Printers when fabricating objects with high complexity. Experiments include models with complex features with variations in curvature, inter-connected parts, intricate details, protrusions, holes and deeply recessed undercuts were built on a 3D Printer. The issues observed include the problem of warping, the need to manually remove support structures, poor dimensional accuracy and surface roughness. |

|

|

|

|

// iDCards //

Loughborough University, 2009; with Dr M.A. Evans (Above) Research findings indicated a need to facilitate greater understanding between industrial designers and engineering designers. The ID Cards provide the name, example and description of 32 design representations used during New Product Development. They indicate when the representations are most employed and if they communicate design information or technical information. The cards are grouped into sketches, drawings, models and prototypes, and 13000 copies are being distributed globally. The ID Card system was developed as part of a research program at Loughborough University and was finalist for the Industrial Designers Society of America (IDSA) IDEA Competition in 2011. An additional 13,000 cards were reproduced in 2013, making a total of 26,000 iDCards in circulation. The cards were shortlisted for the Industrial Designer’s Association of America IDEA 2011 Award and featured in the Loughborough Design School news website. (ISBN: 978 1 907382 35 2). |

|

|

|

|

// CoLab online // 2009 (Above) An interactive CoLab website was developed as a self-initiated project, translating the physical CoLab cards into an interactive website. Further funding was secured from the Royal Academy of Engineering STEM to further enhance the website at a professional level. The CoLab website can be viewed at http://www.eujinpei.com/colab/mainpage.htm |

|

|

|

|

// CoLab // Loughborough University, 2009; with Dr R.I Campbell and Dr

M.A. Evans (Above) The CoLab cards are a result of the PhD degree that aimed to bridge the gap between industrial designers and engineering designers by providing more concise information on the role and significance of design representations. The cards have been commercialised by Loughborough University and sponsored by the Industrial Designers Society of America and are now rebranded as IDCards in a Z-Card format. |

|

...........................................................................................................................

|